We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

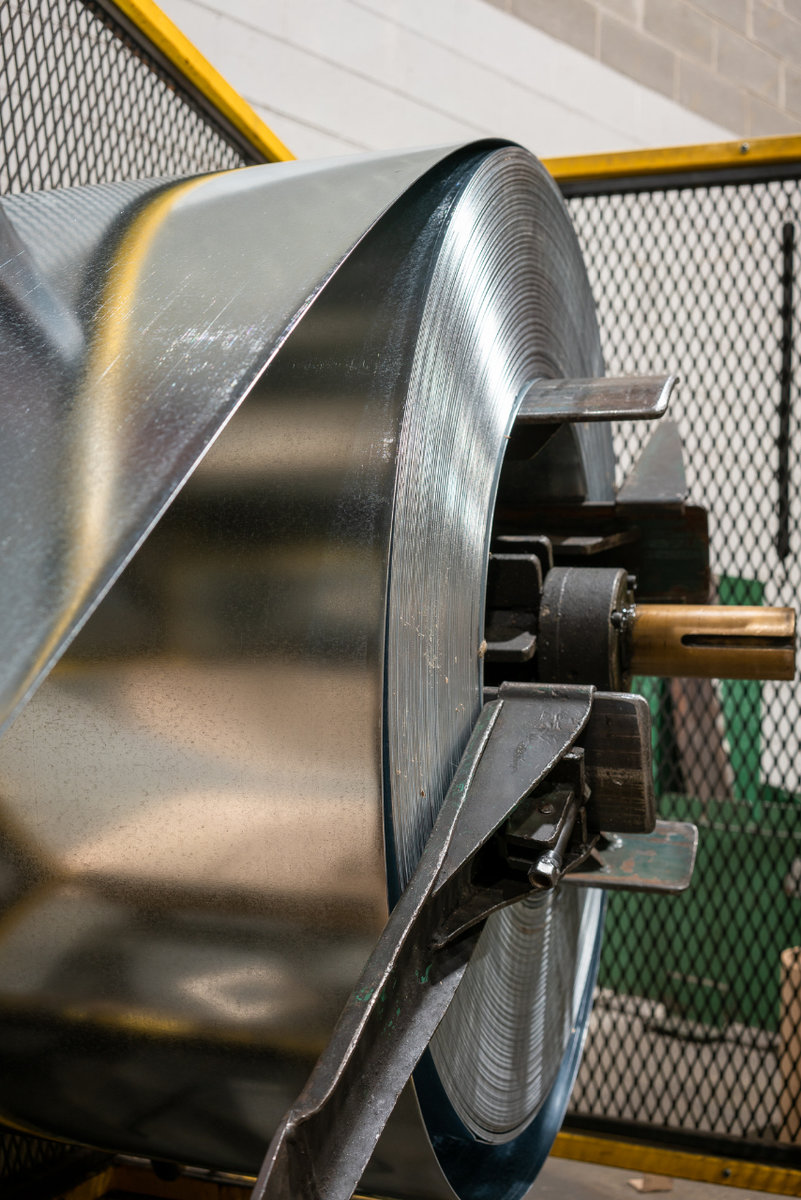

Below are examples of recent custom metal stamping projects completed by Globe Stamping to showcase our versatility and Capabilities of Custom Metal Stamping.

This tier one customer is located in the United States. We create a large variety of stamped metal parts on our high-speed automatic lines for them. We ship directly to their plant weekly, and handle all the paperwork along the way as we provide them FOB their plant pricing.

Due to our success as a custom metal stamping supplier, over the years we continue to add more parts to the population of parts we supply them. This includes custom parts made of aluminum, SS, HRPAO, and CR, and specialty parts finished on hand-feed stamping presses.

We maintain safety stocks enabling us to receive a weekly order on Monday and ship to them by Friday of that week.

ASK A GLOBE EXPERT ABOUT CUSTOM PART NEEDS

Globe Stamping's customer required approximately two hundred thousand custom metal latches a year over a multi-year agreement. We started with the customer's basic metal product design and worked with them to improve the product's manufacturability and cost.

We designed and built three separate metal tools to produce the three components of the latch on our high-speed presses. The cost of the tooling fabrication was incorporated in the first two years of shipments, after which, we reduced the piece price.

Zinc-plated the parts, then complete the latches by riveting them together in our metal stamping assembly department.

After the success of this project, Globe Stamping continues to be the main metal stamping manufacturer for this client.

ASK A GLOBE EXPERT ABOUT PRODUCT DESIGN

Three years ago, we commenced the production of a range of unique in-wall speaker housings and covers, following the departure of the previous manufacturer from the industry.

To ensure a seamless transition for their existing customers, we collaborated with the previous manufacturer to acquire the business, and have since continued to offer the complete product line.

Our selection of speaker housings and covers features various shapes and sizes, including six and ten-inch round housings, as well as six and thirteen-inch square housings.

Due to the substantial stamping and assembly requirements of these products, they were an excellent fit for our plant. Subsequently, we have expanded our capabilities to meet the varying needs of our customers, who often require custom metal stamping variations on these products.

In most cases, we are able to create new metal parts for estimated annual units of 3,000 or more. However, we are also willing to work with existing customers on smaller volume orders.

TALK TO AN EXPERT TOOLMAKER ABOUT MY PROJECT

We recently partnered with a customer who was unsatisfied with their previous supplier of stamped parts. Together, we worked to facilitate the seamless transfer of metal tooling and materials, designing new tools as necessary to improve delivery and customer service. As a result of our collaboration, we were able to significantly reduce the customer's expenses.

The transition was seamless to the customer and no ship dates were missed. Throughout the process, we have been transparent to our customers with respect to our processes and our material costs. Our customer expressed satisfaction with the transition to Globe.