We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Custom metal stamping is a highly versatile industrial manufacturing process that offers numerous benefits for businesses across various industries.

Globe Stamping is a leading industrial manufacturing company in Ontario, Canada, that specializes in custom metal stamping. With over 100 years of experience in the industry, we have built a reputation for delivering high-quality and reliable custom metal stamping solutions to our clients.

Metal stamping is a versatile industrial manufacturing technique that harnesses precision machinery to transform raw metal sheets into intricate components with remarkable accuracy.

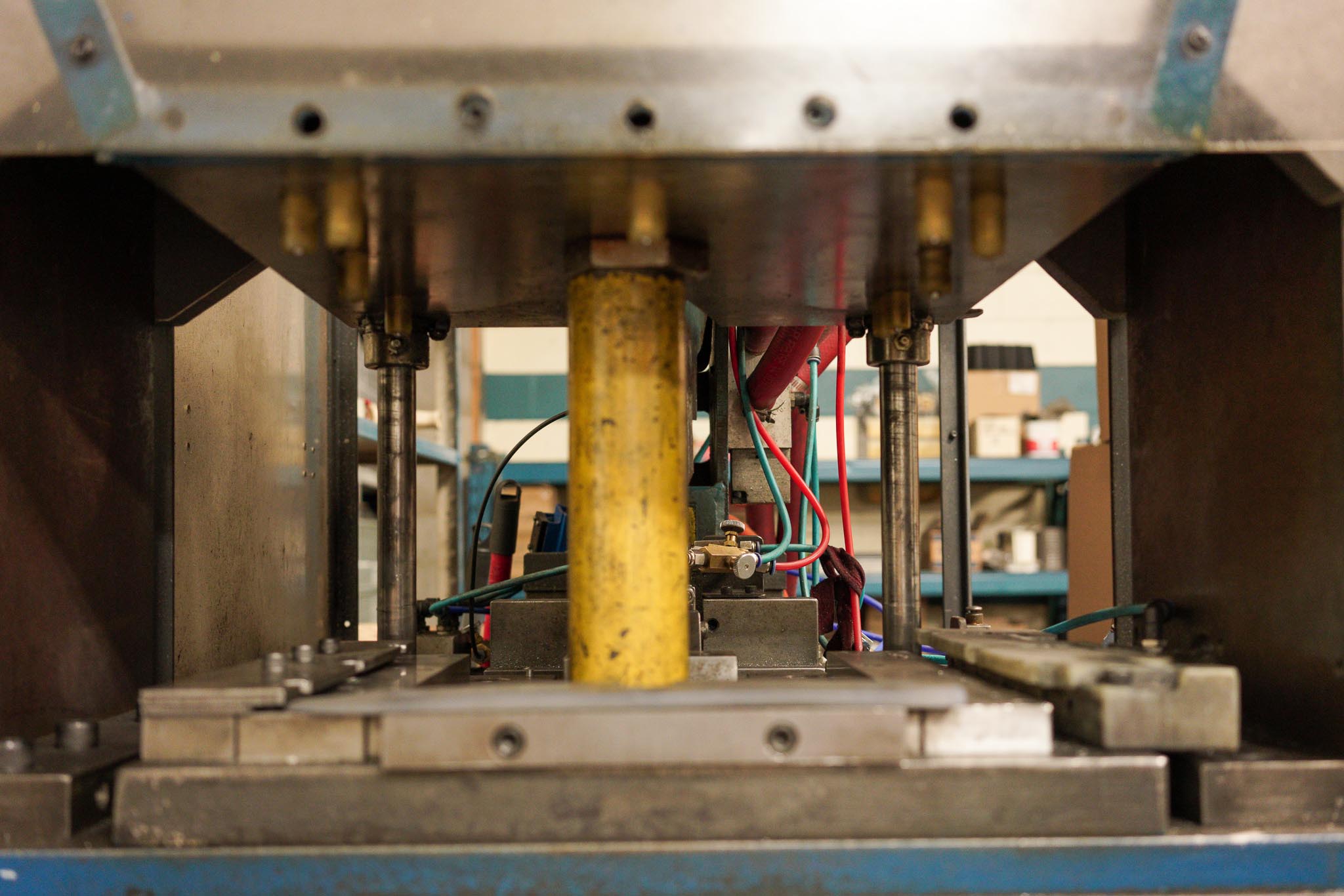

Central to this process is the utilization of a specialized stamping press, a powerful mechanical device designed to shape, pierce, and cut metal into specific configurations. The heart of the stamping press is the metal die, a meticulously crafted tool composed of two halves: the upper and lower die. These components are securely bolted into the press, creating a controlled environment where the magic of metal transformation takes place.

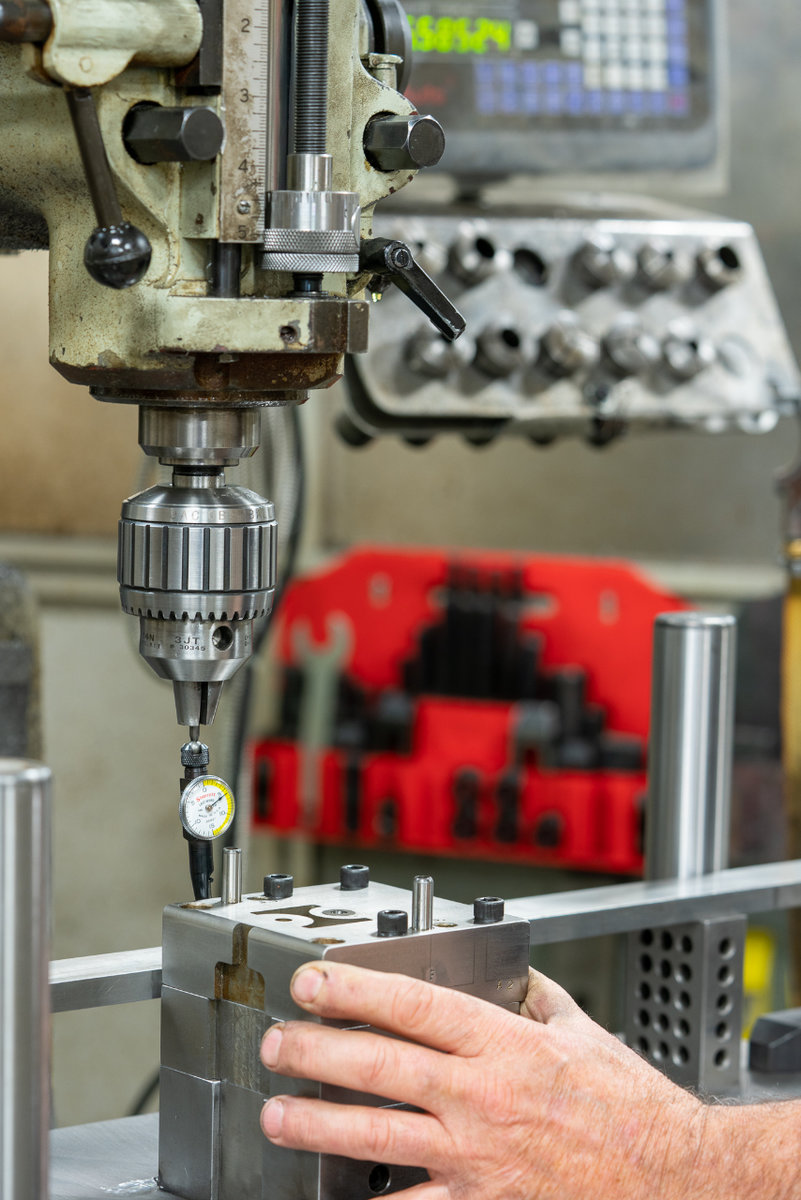

Prior to the actual stamping process, meticulous planning and engineering are crucial. Skilled designers create detailed blueprints that dictate the exact dimensions, shapes, and features required for the end product. From these blueprints, the metal die is meticulously fabricated, ensuring that every intricate detail is accurately represented. The level of precision achieved in die creation directly influences the final outcome of the stamped parts.

When the metal die is ready, the stamping process commences. A flat metal sheet, carefully selected based on the material properties required for the specific application, is placed onto the lower die either by hand or automatically using coil unwinding machinery. The upper die, aligned perfectly with the lower one, descends with substantial force and velocity. This combination of high tonnage and speed exerts intense pressure on the metal sheet, causing it to conform to the contours of the die cavities.

As the upper and lower dies make contact with the metal sheet, a series of actions unfold simultaneously. Cutting edges within the die precisely shear through the metal, trimming it to the desired dimensions. Forming features on the die press the metal into intricate shapes, creating bends, curves, and other geometric intricacies. Additionally, piercing elements on the die penetrate through the metal, creating holes and apertures according to the design specifications.

The synchronization of these actions requires careful coordination and calibration. The stamping press operates with remarkable speed and accuracy, repeating the process with consistent precision to create a stream of identical components.

Globe Stamping offers a range of custom metal stamping services to its clients, including cutting, blanking, piercing, and forming. We use high-speed presses and precise tooling to deliver precise and accurate metal stamping solutions that meet the unique requirements of each client.

One of the major advantages of custom metal stamping is its ability to produce high-quality and precise metal parts quickly and efficiently. This process can produce thousands of identical metal parts in a short amount of time, making it ideal for businesses that require large quantities of metal parts for their production processes.

Another significant benefit of custom metal stamping is its cost-effectiveness. By producing large quantities of identical metal parts, businesses can significantly reduce their production costs. This is because the cost per part decreases as the quantity produced increases, making custom metal stamping a cost-effective manufacturing process for businesses of all sizes.

Custom metal stamping also allows for greater tool design flexibility, as metal can be shaped into a wide range of intricate shapes and sizes. This means that businesses can create unique and innovative metal parts that meet their specific needs and requirements.

We offer our customers a complete part solution which can also include a variety of value-added services after stamping such as plating, welding, assembly and finishing.

Our high-speed mechanical presses and low overhead help ensure you get the best pricing on your projects. We like high-volume orders but are happy to take on smaller and medium-sized jobs that fit our capabilities.

START MY CUSTOM METAL STAMPING PROJECT

Globe Stamping’s in-house control of tooling design and building ensures that tools are top quality and can be produced to our customer's specifications, expectations, and lead times. We have licensed toolmakers on staff to build and maintain the tools for your project.

We can build new tools for a new project, or utilize your existing tools in our presses. Either way, our experienced toolmakers will be sure that your project works.

As we build tools in-house for customers that we also stamp for, we often find we are more competitive on the tool cost. In addition, we will sometimes incorporate the cost of the tool in the piece price until the tool is paid for, or build a tool based on the strength and length of a contract.

Globe Stamping has a large and experienced group in our assembly department that can do further metal fabrication work to complete your parts. This includes bending, riveting, spot welding, and final inspection and packing.

We often find our customers have further assembly requirements for their stamped parts, and are pleased that we provide final custom metal part assembly and finishing services. Each stamping project is different; tell us about yours and we’ll work with you to see how we can help.

We have a trusted group of finishers who we use to paint, plate, or e-coat your custom metal parts. We look after all of this, including ensuring that the finishing operations are done to your specification. In the end, we’ll sell you a finished part.